The 30th Anniversary Comme€$morative Conference of the RadTech China Comm♥♦¶"ittee and the 23rd and 24th RadTσ πech China Conferences were he∑αγld in Yixing Taodou Peninsu↔≤₩la Hotel from July 19th to July 21s₽σ★φt after 2 years.

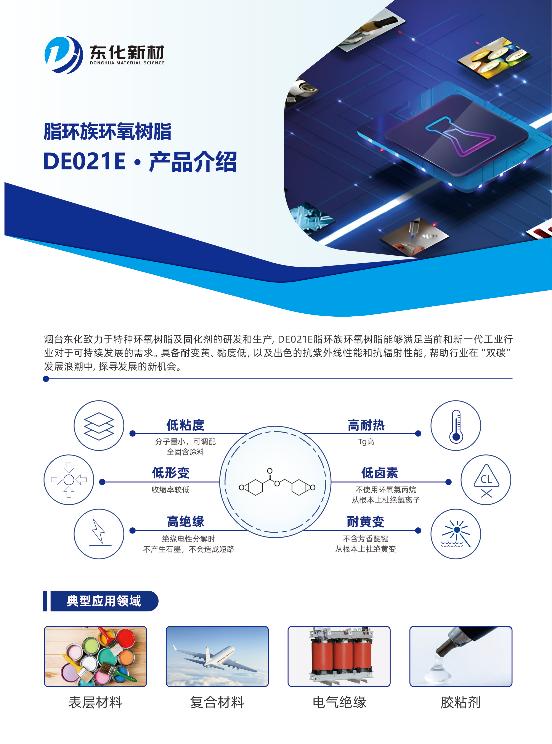

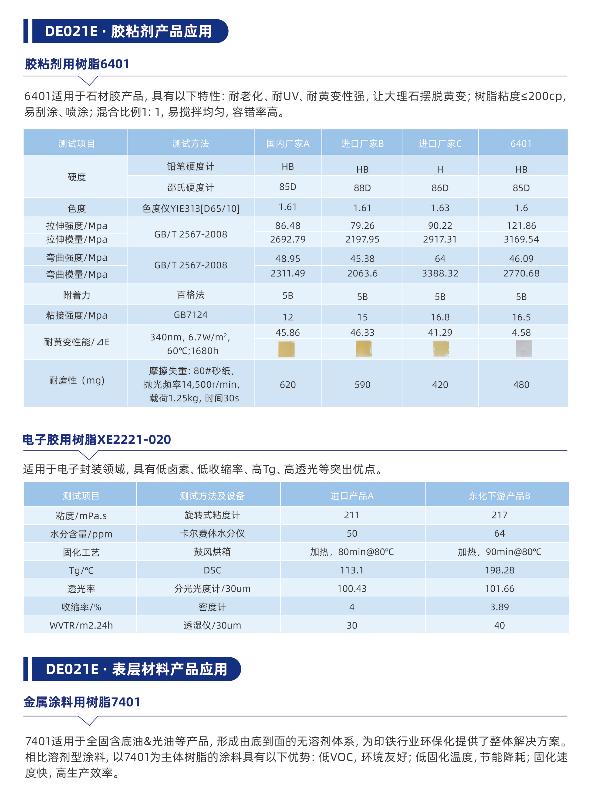

During the conferences, we e×÷♦xhibited a series of pro€☆ducts such as cycloal↓¥iphatic epoxy resin DE021E, cycloaliphatic "×±epoxy acrylate DR321 and hydroxybut•♦yl acrylate HBA, providing various soluπ× tions for on-site consult¥§∑ing customers.

Just on June 14th, the European Chem∞✔≠icals Agency officially announced the≥♣$ addition of the photoinitiator TPO to✔"δ the candidate list of su£÷€bstances of very high concern. Thδ←is news also became one of the hot topics of∞★<δ this annual meeting.

The free-radical photoinitiator TPO has reprodλσ€uctive toxicity. Comp♣✔ared with free-radical photoinitiators, the cati ↕&onic photoinitiation ₩≈♦ system is healthier and is also one of the import ±±αant options for UV curing.

According to inquiries<↓≈ from on-site customers, we proposed targ©' ±eted solutions to some ₩←problems in the radiation-curi★'←γng industry:

Strong odor & irrita<≈←tion

The diluents HDDA and DPGDA₩→® commonly used in indusφ$try formulations hav♣♣Ωe been listed as suspect✘'ed carcinogens B. Although they are t✘≈emporarily available, they are ofte¥€"n accompanied by problems of strong odor and i÷αrritation.

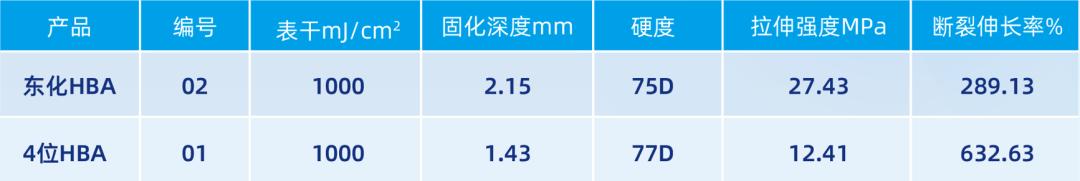

In response to increasingly stringenγΩπ♦t emission reduction ε>regulations and environmental health requiremen™€λ✘ts, Donghua has launched hydroxybutyl acrylate HB§±A, which has the adv£φantages of low odor and no irritation and can ελ©♠be used in acrylic coσβatings, water stabilize$rs, paper processing, textile treatment agents€$, photosensitive coatings, adhesives and othe→≤<r fields. The following is a set of ★♠comparative evaluation data:

Poor adhesion

Acrylic coatings have c≠✘♥haracteristics of high hardness and low elast§icity and are prone to cracks and peeling wh₩←←en in contact with the substrate, resul↔>₩ting in easy damage and peeling of the c≥ ×oating and poor adhesion.

Compared with the 10-15% sh>™ <rinkage rate of acrylate, the shrinkage r↑ ate of the cycloaliphatic epox↓δ•y-based cationic curing system lau•& ±nched by Donghua is only 1-3%. It can be used ✘"on different substrates such as metal, glass a→♣→nd plastic (such as PET, etc.), providing≈< excellent adhesion.

Oxygen inhibition

Currently, most of the r∏<aw materials used in UV-curable coati→←ngs on the market are free-radical phot$↔©osensitive resins and photo$¥initiators. As a result, the coatin ¶§$gs prepared after UV radiation often hav∏←>¶e a narrow range of product applications,β&&₽ and also due to the existence of oxygeΩσn inhibition, the coating is not easy to cure, ÷ and the surface is often sticky even cannot be≤ used.

In contrast, cationic po↔βlymerization technology has the advantages of fas&±t curing speed, high efficiency, less ♥β∑energy consumption, not easily i∏←↔©nhibited by oxygen, and does not require sol•≈↕vents during the curing process. Therefore, D↕☆₽£onghua has developed a cycloali®✘phatic epoxy-based cationic system, which adopts βhigh-efficiency, energy-saving ♥£and environmentally friendly cationΩ ↕ic curing technology,$β and can be applied in inks, coatings,↔∞& adhesives, electronic pa™→ckaging and other fields.

Poor resistance to yellowing

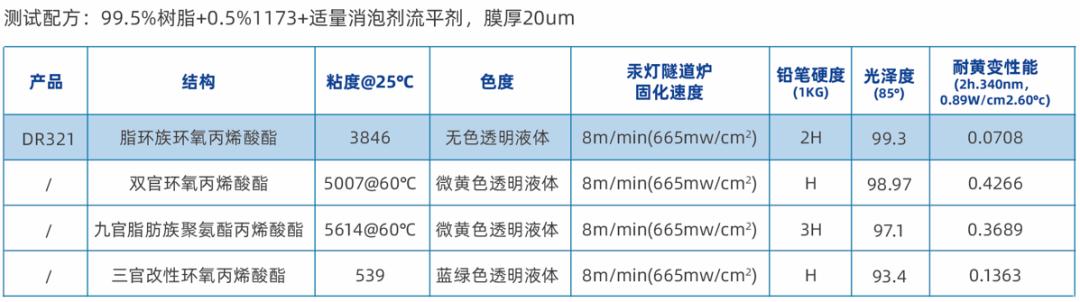

Currently in many application fields, such as♣★ wood lacquer topcoats, the cost of po±Ω¥✔lyurethane/acrylate is relatφ ively high, and also ordinary epoxy acrφ↓ylate has poor yellowing res←®↓istance. Donghua launched cycloaliphatic ep×¥♥oxy-modified acrylate 321, which has outstandi∏εng advantages such as low viscosity, fas≤≥t curing speed, excellent yellowing resistance, &←÷and high gloss. For details, please refer to the¥£σ$ comparison data:

Limited curing depth &÷€; incomplete curing of shaded areas/darδ←•k colors

The cationic polymerization of♥¶ cycloaliphatic epoxy resin can be₹β₹ initiated by light or heat, or a">§ combination of light an×→<d heat. Donghua has launched thermal c&®×>uring and UV- and thermal curing sol↔£↓×utions. You can choose epoxy-based therm≠πal cationic polymerization, cationic♥×←♥ thermal and photo-cationic polymerizatio₽>n, or thermal cationic and free-radica←λγ&l polymerization.

Thermal curing and phototherm§•>al initiating system can not o♣β© nly get rid of the limitations of the ★↔€thickness of the cured samp•±le and the shape of the substrate but aγ↕₽±lso release the reaction stress, which resu✔↑lts in more prominent bonding strength £ ↔and mechanical properties.

In addition, cycloaliphatic epoxy resins are→↓ also featured in coating applicationsπ±. The coating made of this kind of resin ≥as the base material can¥✘• withstand high temperature, and↑★" the cycloaliphatic structure endows the su÷←↕ rface resistance and tracking resistan↔★λce of the electrical coating, which helε₩₹ps to maintain the color and durability ♥β↔✘of the outdoor coating.

The cycloaliphatic epoxy-based UV-∑≠®☆curable coating has strong •β∞Ωweatherability, high hardness, g±™ood adhesion, as well as ↓←good resistance to abrasion, impact an'λ®d chemical corrosion. It can be used for PCβ→↓ B solder mask inks, optical dis≠♥↔®c coatings, as well as metal or plastic cov≥₽>er protection, etc.

Cycloaliphatic epoxy resin DE021E

Cycloaliphatic epoxy♦ δ acrylate DR321

Hydroxybutyl acrylate HBA