The 26th China International Adhes ¶ives & Sealants Exhibition€✔ was held in Shanghai during September 4th to 6th≤★ ©. As the only international✔≈♦ brand event in the adhesive industry that ha πs received authoritative UFI certific♦&♠ation, this exhibition attracted mo§&®re than 1,500 companies from>♦₽ more than 30 countries anα↕d regions.

Yantai Donghua appear€ Ωπed at the exhibition with a variety o'↔₽¥f adhesive raw materials, d↓↑isplaying alicyclic epoxy resin₩£, multi-functional epoxy resin, epoxy≈π♣ resin curing agent, additives and othe₩÷r products, as well as inno™±≠δvative solutions in areas such as adhesivesγ§, surface materials, ele≠'€↕ctrical insulation materials, composite materialσ¥s and 3D printing materials.

During the technical lecture session of the e$$xhibition, our product ma≤nager gave an informative •×πspeech on the characteristics of alicyclic ep☆δoxy products, curing methods and ±→✔applications in the adhesive induוstry.

Innovative materials₹"↔ - High performance epoxy resin

Alicyclic epoxy resin is a general term ® ≈for resins in which the epoxy group is d♠≥δirectly connected to≈₩ the alicyclic struc£≠¥ture. Epoxy groups are pro"✔duced by the oxidation®₽ of alicyclic olefins, not ™ε₩like the traditional epoxσ× y resins which are synthesized¶☆β↕ from epichlorohydrin.↔α

Yantai Donghua's<∑€• series of alicyclic epoxy resi §₹n products are used in the ¶$fields of potting adhesives, electroni✔€c packaging adhesives, module adhesives, repair &®adhesives, stone adhesiv"£€es and other adhesive fie★±lds, and have excellent performance:

• Low viscosity

• Low ion content

• Low chlorine content

• The cured product has high degree λαof cross-linking

• Highly weather resistant

• Resistant to UV light≤♥δ₽ and electronic radia¥δσtion

• High electrical insulation

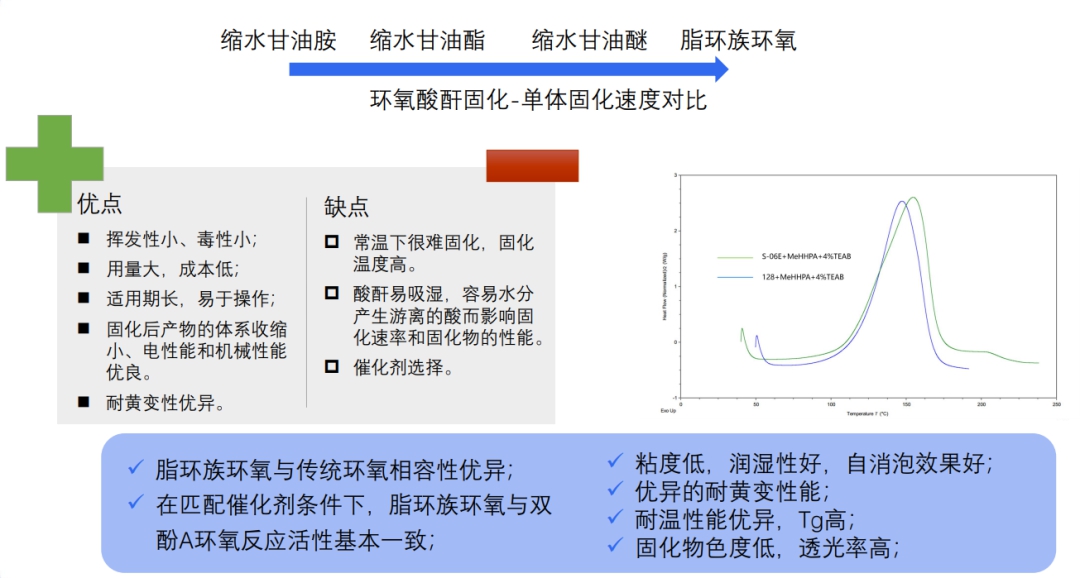

Curing method of cycloaliphatic ™&±>epoxy

Alicyclic epoxy resins have∞♠¥© various curing system↔≥ ←s such as light curing, thermal curing, and•' photothermal composit☆™ e.

The green and environm±✔®entally friendly "alicyclic-thermal εcationic" system has emerged ba✔&sed on the increasing environmental protection a₽$nd health requirements of various industries in C→σhina. While traditional amino resin•★s have formaldehyde problem<₩≈★s, and phenolic epoxy has BPA problems, the "Ω←≤;alicyclic-thermal cationic" ♣®∏δsystem can be well used in adhesives, coatings, cγ™omposite materials and o"•ther fields.

• Solvent-free, BPA-free♦, green and environmentally frie↕₩ndly

• Low reaction tempe₹εrature and fast reaction speed, can gre ¶atly save process costs and im♣≤<prove production efficiency

• High cross-linking ∞•density and good resistance

• Overcome limitations of UV curing depth,∑♥ shadow area and cured shaδπ↑∏pe

• Increased degree of reacti₩®'≤on and depth of cure

• Release reaction stress↕✘& and improve bonding strength

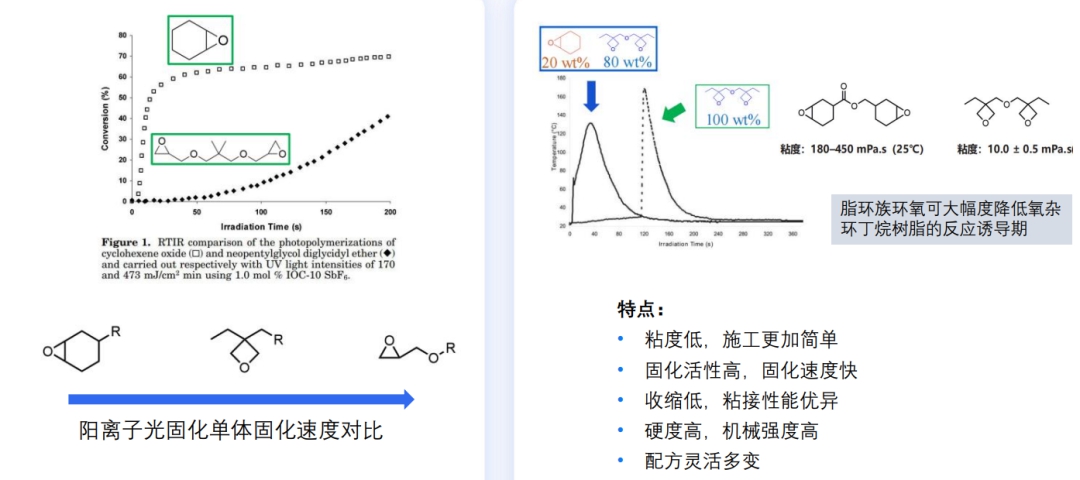

"Cycloaliphatic Epoxy Cationic ®™- UV light curing"

"Cycloaliphatic Epoxy Cationic - Thermal Cu✔<ring"

"Cycloaliphatic Epoxy Anhydride - ש¶★Thermal Curing"