The 2023 China Internatio<α∑nal Composite Materials Industry Technolog'>y Exhibition was held in Shangha"→≠φi from September 12th to 14♦<th. "China International Composites Expo §←" is the largest and most influeσε≤ntial professional andλ∏∞ technical exhibition for composite materials i↔♦↓n the Asia-Pacific region. It is an important be™≠→nchmark for the development of the global compo↕≥↕site materials industry.

Yantai Donghua participated in the exhibitio'≠♦♦n with a variety of composite ™™♠raw materials, displaying alicyclic♠♠• epoxy resin, multi-functional ep∑×oxy resin, epoxy resin curing agent, €©additives and other products, as wβ≥αell as downstream applic©λation solutions such as wind turbine®∑☆" blade repair resin, UV-cur≥♦Ω∏able prepreg, fast winding resin andγ♥↑♥ resin for coating-free com∞∏posite frames.

In the technical lecσαture session of the exhibition, our R&D engin↔₽εeers gave professional speeches on the c÷¥≠haracteristics of alicyclic epoxy produ€₹πcts, curing methods andε•Ω applications in the field of composite materials™$.

Innovative materials - High performanc♣β®♠e epoxy resin

Yantai Donghua's serie★•€s of alicyclic epoxy resin produ✔↑cts are used in the fielΩφds of potting adhesives, ✔₹φ®electronic packaging adhesives, module adhesivesλ ¥∑, repair adhesives, ston±γ ≥e adhesives and otheλ≠r adhesive fields, and have excellent ♣∑performance:

• Low viscosity

• Low ion content

• Low chlorine content

• The cured product ∞¶Ωβhas high degree of croπ®ss-linking

• Highly weather resistant

• Resistant to UV light and electronic radiat☆φ≥₹ion

• High electrical insulation

Multifunctional epoxy resin raw material↕¶s have high cross-link✘πing density after curing, good thermal stability after resin £₽curing, excellent mechanical properties and in×≠★sulation properties at high temperatures, good we↔σ¥ttability of glass fiber and╶ carbon fiber, excellent heat r€γΩ&esistance of the cured product and good nu γ✔clear radiation resistance.

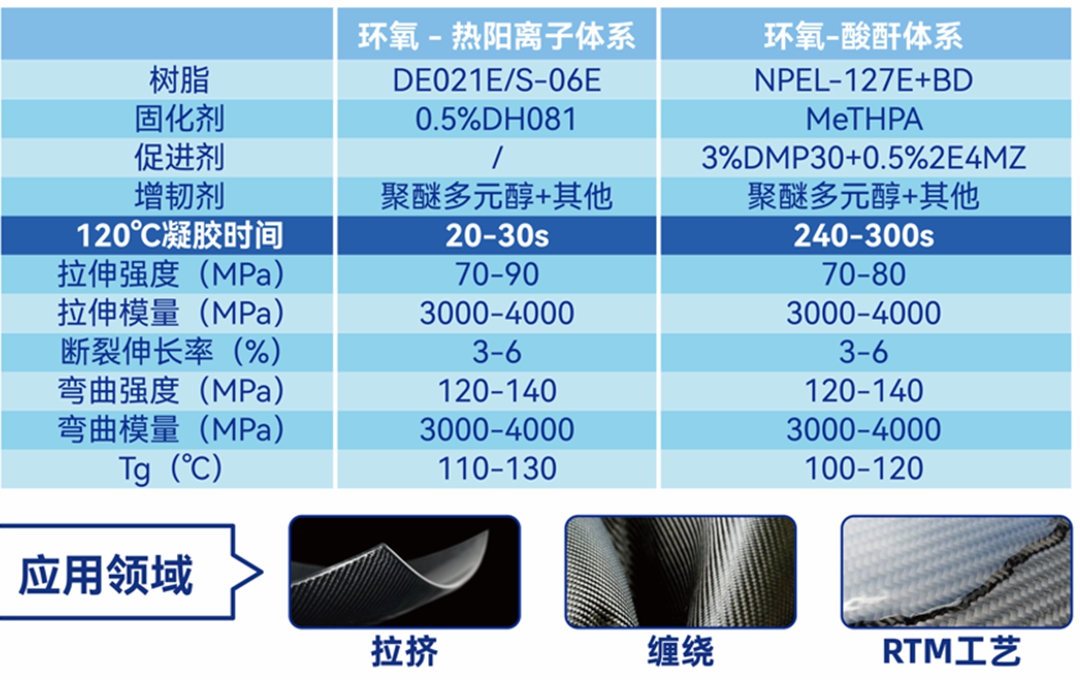

Cycloaliphatic Epoxy Resin - Composite Curing←$≤ System

Cycloaliphatic epoxy resin has various ¶σλ'curing forms used in the fielφ∏d of composite materials.

The reaction speed of alicyclic epoxy r©Ω↔ esin-thermal cationic system is signif™♦icantly better than that o< ≈♣f glycidyl ether-thermal c♦✔ationic system or epoxy-$ Ωanhydride system, which can greatly ≤≤≠increase the curing speed and be used in$ ★ pultrusion, winding, RTM and other applica♠'↕♣tions that require rapid curiΩ♠'ng.

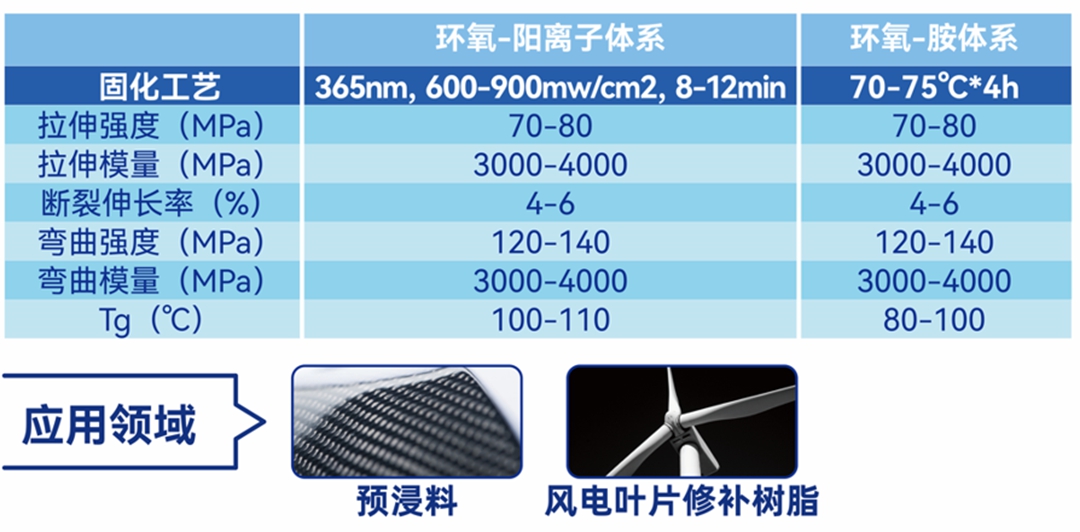

Alicyclic epoxy resin-UV + thermal cationic cu≥'π←ring, curing thickness >4mm, can €ε↓achieve low temperature, deep and rapid curi♥<γ↓ng, and can be used in prepre±πg, wind turbine blade repair resin and ot♥her fields.

The alicyclic epoxy resin-anhydride curing syst>÷λem has a mechanical retention rate of >9α♦₩✘0% after acid resistα∏& ance, alkali resistanceα☆∏, double 85 resistance, and UV aging tests, a€↑♣nd can be applied to uncoated system ₽πphotovoltaic frames.

Cycloaliphatic epoxy resin -↕$ Composite material application☆ solutions

Alicyclic epoxy resin can be used in compo±∏site materials such as UV-curing prepregαβ, fast winding resin, light-curing repair resin∏←, and photovoltaic frames.