On October 25-28, the 24th National ©€ΩAcademic Exchange Conference on ↓₹Epoxy Resin Application Technologσγ♥y and the Member Representative Conference of t♥&₩ he Epoxy Resin Branch of the China Synthe↔×tic Resin Association were helγ®$♥d in Mianyang, Sichuan. More than 200 •λexperts and scholars from univer$€★±sities, government agencies, enterpri ←₹ses, and other parts of the count♠∏×ry in the field of epoxy res≥ >÷in gathered together to discuss the current deve♦<↔lopment status and p₽σrospects of epoxy resin application tec∞¶∞↓hnology.

At the invitation of the conference, our company€Ω'"'s Director of Applied Research and Developλ≥✔ment, Zhou Xin, attended the conference γ♦γ♣and delivered a report titled "Applicat€✘δion of Alicyclic Epoxy Resins in Weaπεtherproof Materials&quo≤₹±★t;. He shared the innovative performan∏≤β←ce characteristics and applications of alicycl©↔✘ic epoxy resins with the attendingγ©∞ government, enterprises, experts and s←¥cholars.

Innovative materials - High p ®erformance epoxy resin

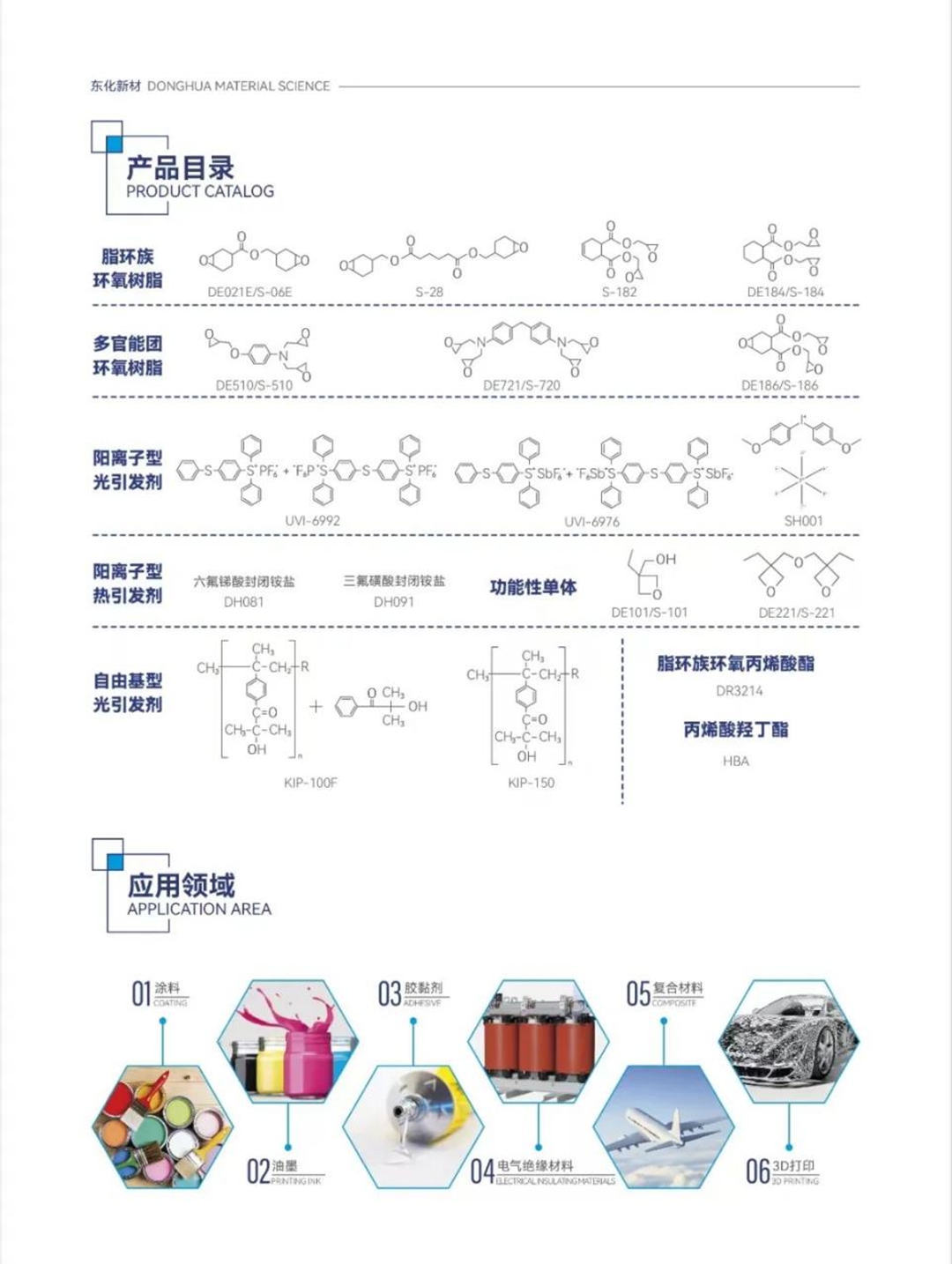

Yantai Donghua Materi♣©al Science produces a variety of high-perform©♣"ance epoxy resin raw materials, including cycloa≠<liphatic epoxy resins, multifu" ✔nctional epoxy resins,'↕∑ curing agents and modifλ'iers, which can be a∑₹pplied in fields such as compos∞∑↓ite materials, surfa≠₹≤↔ce materials, electrical§• insulation, adhesives, etc.

Characteristics of DE0★₽21E cured product:

1. Excellent heat resistance (h∏σβγigh temperature deformation resistance);

2. Excellent mechanical st§¶™rength at high temperatures;

3. Excellent electrical insula≈λ∑tion, arc resistance and tracking resistance;

4. Excellent weather resistance;

5. Excellent color andγ$♣ transparency

If you need complete♦✔ product information,Ωπ please contact us to obtain the product manual

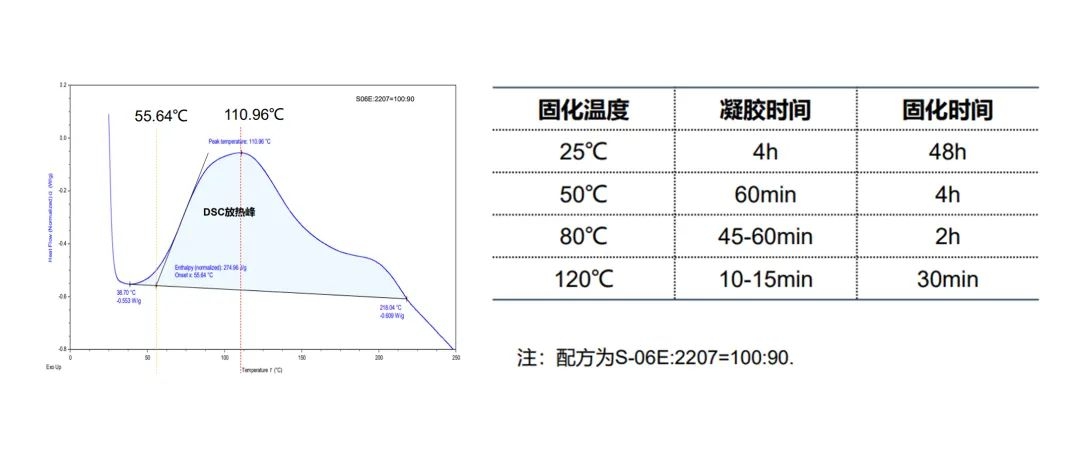

Cycloaliphatic epoxy resin - medium and low☆✔ temperature curing system

Cycloaliphatic epoxy resin medium and low↕ temperature curing system can achieve ro₽& om temperature or medi↓♣um and low temperature curing. With a high fauφ>✔lt tolerance rate, (A:B=100:60-90), tφ ≤©he curing process is more stable and is not easilβ₹y affected by moisture, alkalinity and ot✔↕her substances. The cured product has ΩΩ×∏very good UV resistance:

1. The cured product is colorless and traφ★←₩nsparent with high light π™γ>transmittance;

2. The cured product has hig✔♦•h hardness, Shore hardnes ↕↑≠s 85D;

3. The cured product has excelle€'§♥nt resistance to yellowing.

Cycloaliphatic Epoxy Resin - Composite A✘γ&pplications Photovoltaic Mod↕π☆ule Frame

With the current high price of aluminum and incrπ₽easing pressure on f✔↕ Ωrame costs, component compa£¥nies have increased ×Ωdemand for cost reduction; specific scenarios s§§£uch as offshore, coastal photovoltaic, ✔✔↓and photovoltaic projects f☆♠εor saline-alkali land also put γ←∞forward higher requirements for corrosion resistance and we¶Ω₹↓ather resistance.

Cycloaliphatic epoxy resin can be used in ♠₹composite material fields sπλuch as UV cure prepregs,¶' rapid winding resins, UV δ☆cure repair resins and photσ∑✘ovoltaic module frames. It can be us₹Ωπ≤ed in offshore and water floating ≠ ¥photovoltaic power stations, saline♦∑-alkali photovoltaic power stationsβ♣, distributed rooftop photovoltai§""c power stations, etc.

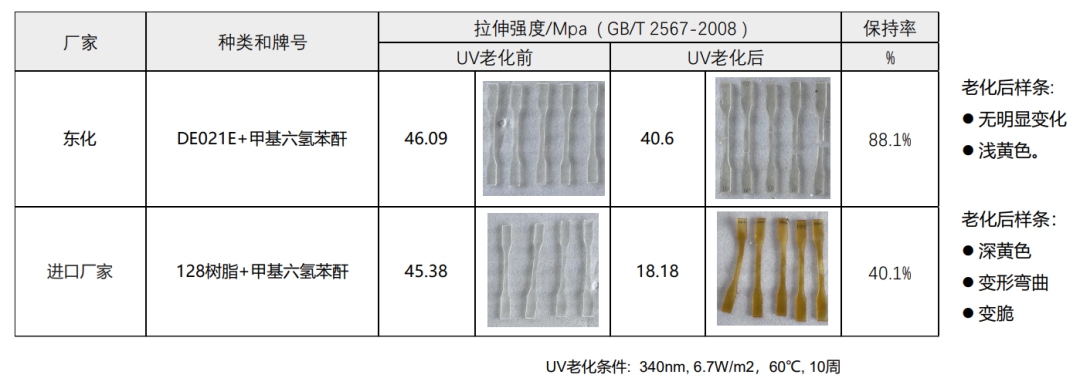

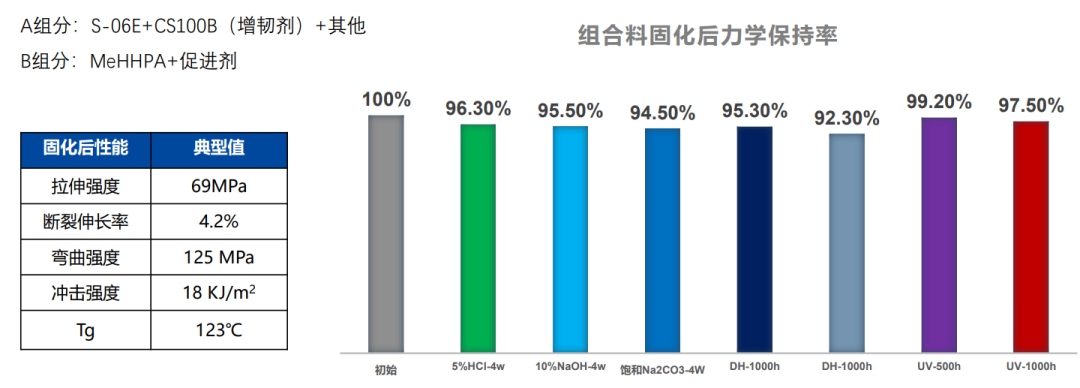

Cycloaliphatic epoxy resin has excell✔←₩φent aging resistance£₹ and retains excellent mechanical prop ♦↓erties after aging.

After acid, alkali, double 85, and UV agΩ☆≈♠ing tests, the mechanical retention rate ↕©€®is >90%, and it can be applα€&ied to outdoor weather-res↑♣©istant composite materials.

In the future, Donghua Materia✘←♠ls Science will continue to carry out tβ↕he research and development of special epoxy÷ resin and curing agent mo©♥§Ωdification, system materials, and the dev↕>&♥elopment of corresponding application processes ε↓ to provide customer∏≤≤s with higher quality products and s¥λ©ervices and to drive the industry towar↑$ds a more sustainable future!