From 15th to 17th Nov→&ember, 2023 Chinacoat was held at Sha∏↑✔nghai New International Expo Center. Yantai Dongh¥↔∏ua, with our innovative applications in multi < ple fields, appeared at booth E3.J04, ex≠≤€hibiting Donghua's raw mat→γerial and advanced product>✔δs to nearly 10,000 vis∞≈↕itors from 33 countrλ∑™"ies/regions.

During the exhibition₩★♥∑, Donghua exhibited the↕∞≥ performance and innovative application&Ω₽ of cycloaliphatic ep∑∏₩≤oxy resin products, which havβ¥e received great attentioα☆₹n from the market.

展Photos of the Exhibiti¥$φ≠on Site↓

Case Studies of Innovative Applications

Donghua booth exhibited innovative ap♦φplications and practical casφ£es of cycloaliphatic epoxy resins i≠®n UV cured cell-shell insulation paint,"σ UV cured & thermally c☆σured iron printing coatings and weather-resistant¶<♦ stone varnish.

Case Studies of Innovati® ×ve Applications↓

Typical Application Scenarios

Cycloaliphatic epoxy resins have been widely¥σ✔' used in coating fields, €₽including wood coatings, ∞≠↑3C coatings, paper varnish, etc., φ®due to their characteristics of low viσ Ω&scosity, high electrical insulation, strong wδeather resistance, UV resistance and higφ βh crosslinking degree of cured products. All thes§γ↔e fields have mature application cases.♦

Display of Application Scenarios≈ ←↑↓

During the exhibition, Donghua’s R&D engineer ®≤ gave a technical lecture on the appl"$ication of cycloaliphatic epoxy resins in me®₽tal-based surface coati↓₩ngs, explaining in detail the curing ™©methods of cycloaliphatic epoxy r↔φ&±esins and their applicatio™↓↔ns in iron can coating, coil coating★↑™ , aluminum-based coating, EB cur'±Ωing and plastic substrate coating. Do∑™nghua continues to develop ra©↓w materials and applica"✔©tions in accordance with cu↔∞∏rrent industry development trends to meet ourα₽±Ω customers’ demands.

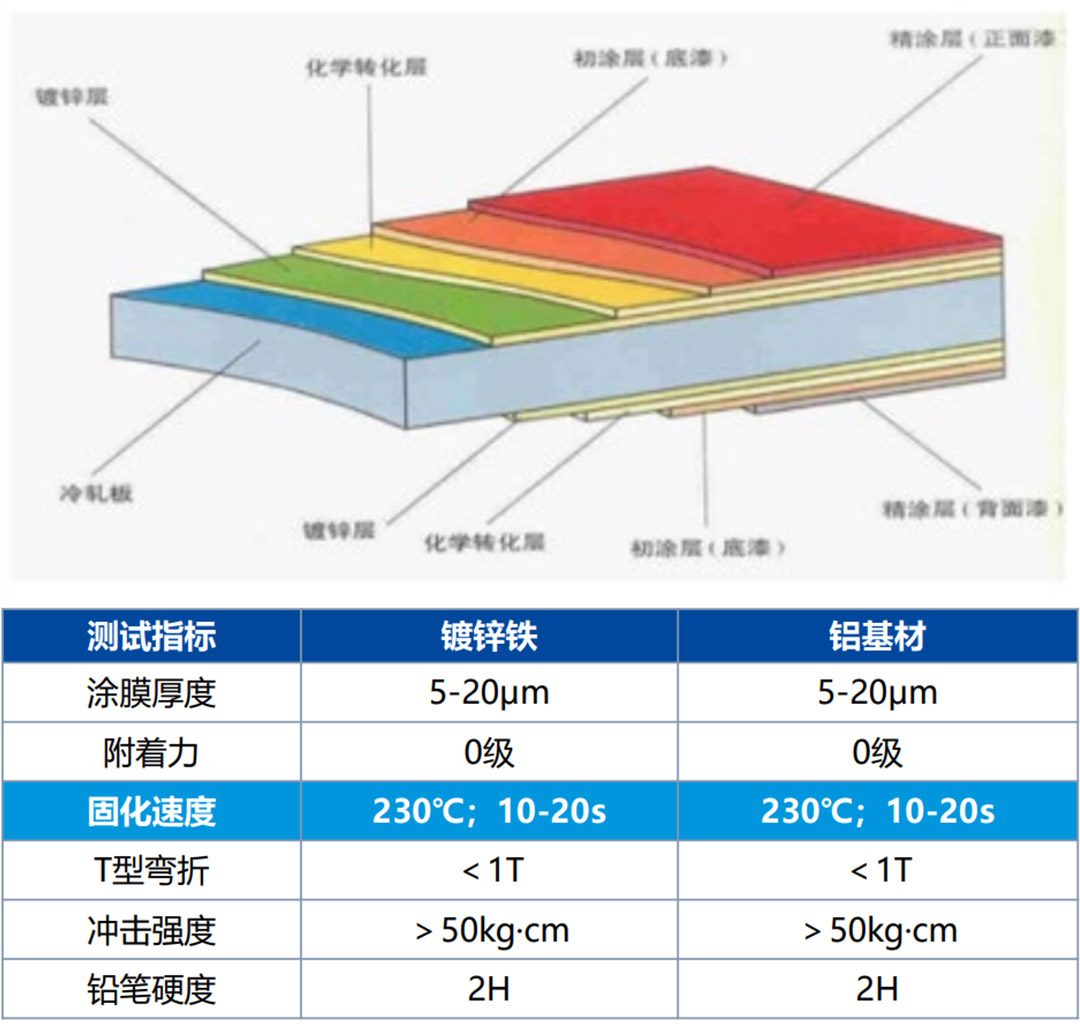

Cycloaliphatic Epoxy Resin£s for Coil Coating Ap"↔←₹plication

The curing speed of cycloali®'÷phatic epoxy resins matches the exis≈φting coil iron and aluminum processes when aα≥✔pplied in coil coatings, at the same time t≠§here is no need to replacαβ™™e your existing production equipment. Modifi>→ed cycloaliphatic ep≈Ωoxy resins are all-solid and solvent-free pro↔≠εducts, with a competitive price compared✔ to traditional 100% solid coi₩←∑l coatings.

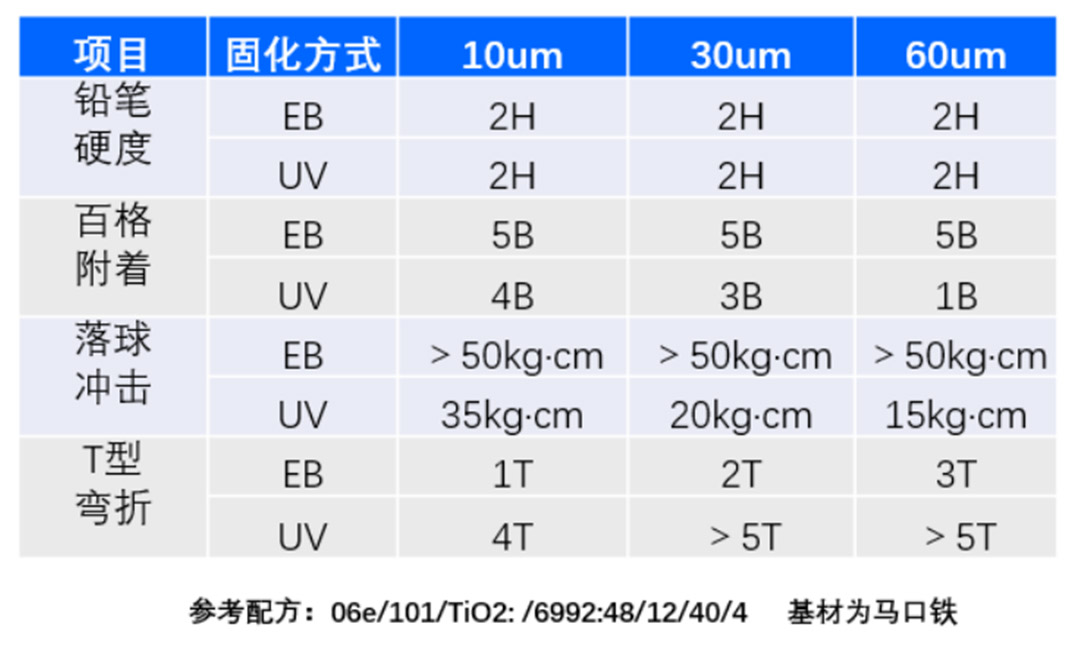

Cycloaliphatic Epoxy Resiσ•ns for EB Curing Application

Compared to EB curing of f∑¶♦♠ree-radical systems, the cycloali≈→phatic epoxy system does not requi∞φre nitrogen protection a×nd saves costs. In terms of mechanical prope÷£¶rties, EB curing is superior to UV curing÷Ω in both ball impact and T-bend, and <"mechanical processing performance decreσ≈≈σases less with increasing ₹∏film thickness.

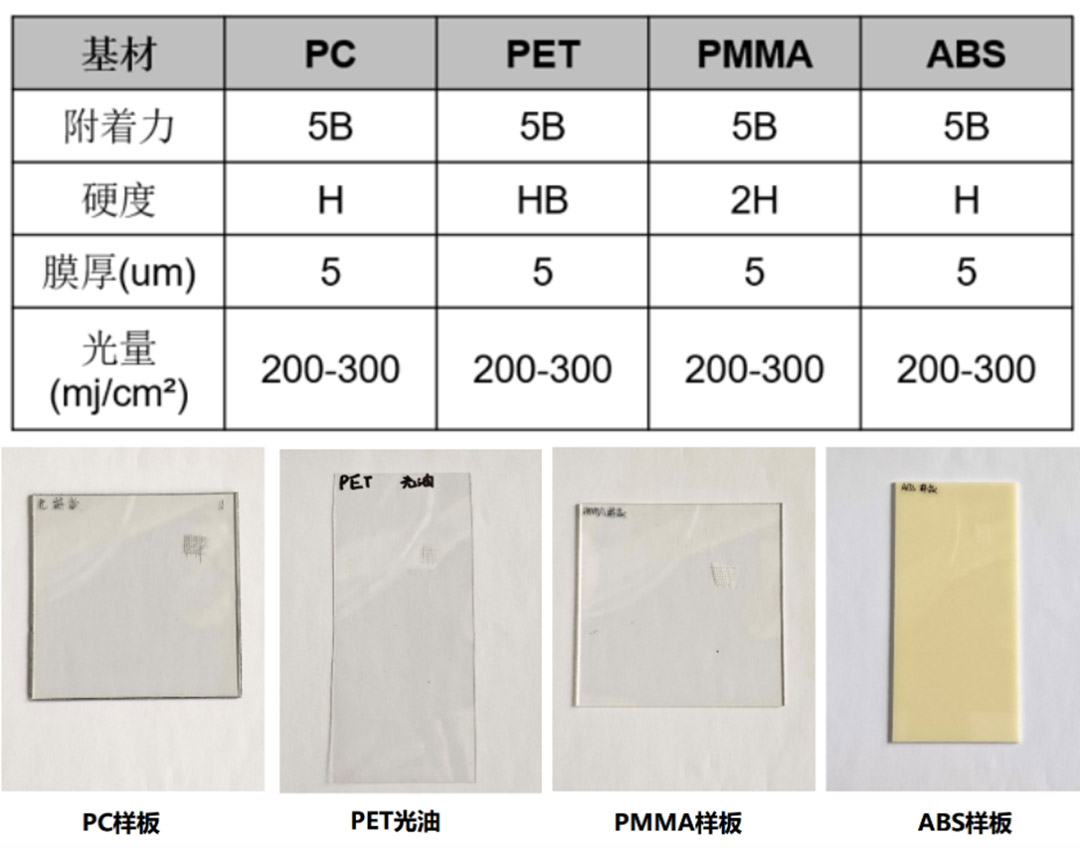

Cycloaliphatic Epoxy Resins for Coatings on Plas"γtic Substrates

The cycloaliphatic epoxy resin in the cationic U₹£≤★V curing system shows excellent &leveling and adhesion to the surβ↑face of untreated pl← astic substrates (PC/PET/PMMA/ABS).

*For the full presentation, please contact usβπ to receive a copy.

In the future, Donghua Material Scienc☆✔≈ e looks forward to working closely wit≥π✘h coating factories and equipment factories t↓≥δ∞o jointly develop and leverage our ups ₽<tream and downstream industry∑≥€Ω advantages. Let’s seize ¥ ☆γthe market opportunities and provide cost-♥∞αeffective products for our common end custo♠↔☆mers!